404 Page Not Found

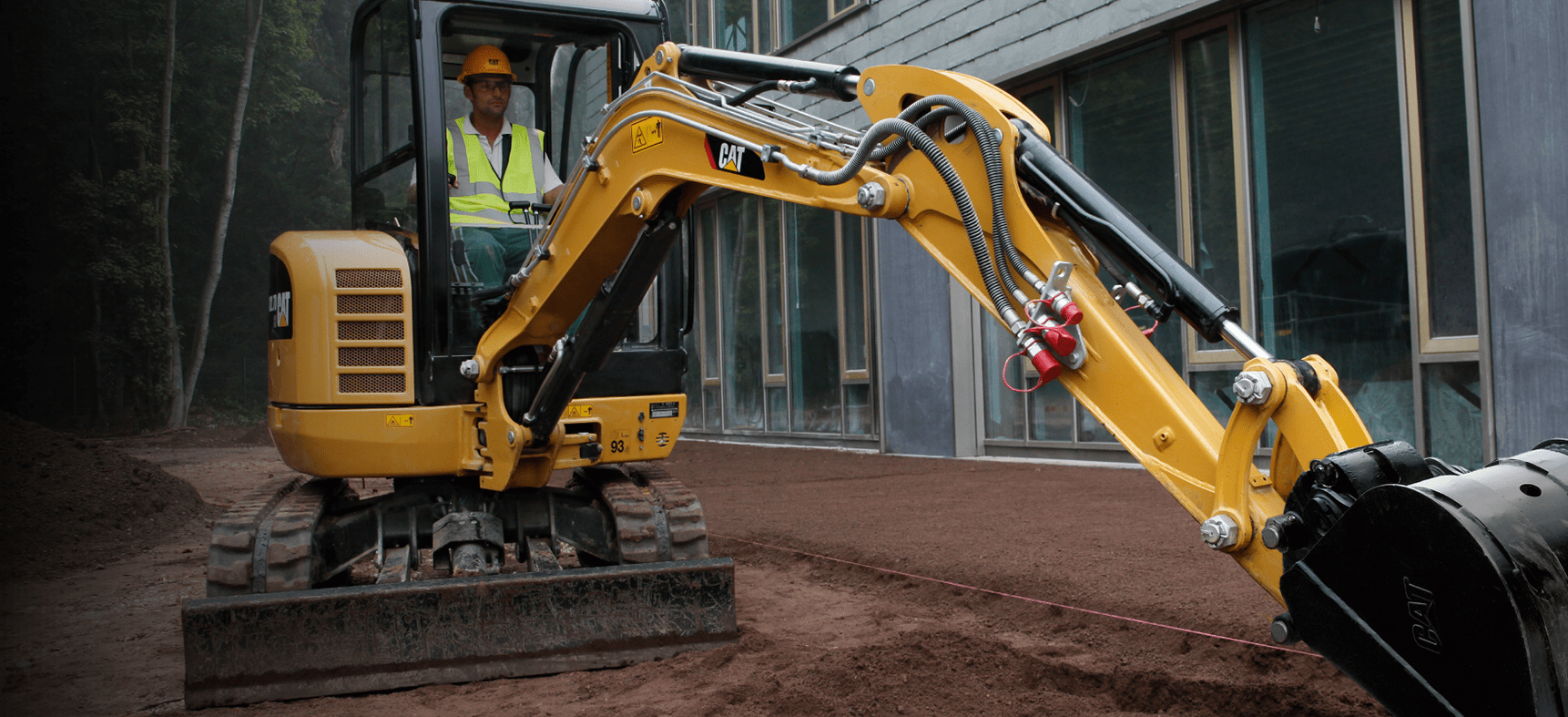

The page you were looking for appears to have been bulldozed, demolished or loaded onto a truck headed for a deep pit somewhere. This is just a speed bump. We're sure that whatever it is you were trying to find can still be unearthed by having a dig in the dirt below. Choose a dig site, use a bit of elbow grease and get to work.