Hose solution improves run time by up to 50% for DJ and JA Brooker (2020)

A solution that allows custom hoses to be built on demand and to precise Caterpillar® specifications has helped long-term WesTrac customer DJ and JA Brooker increase their average machine run time by up to 50%, create a safer working environment and apply real savings to their bottom line.

DJ and JA Brooker director Jason Brooker says the company, which was established in 1989, today runs a fleet of 14 machines, 13 of which are Cat® brand.

“We purchased our first Cat machine 25 years ago and it’s been our preference ever since,” Jason said.

"We have a sizeable operation, so ensuring machine reliability is absolutely essential for our business. As the company grew, our machines inevitably saw an increase in operating hours. This meant additional strain on parts, including hoses, and we were blowing between three and five every month.”

When a machine goes down because of a hose issue, there is usually a delay – and subsequent loss of operating revenue – while the new hose is fitted.

Each delay may be small but across the Brooker fleet, the combined downtime was having a considerable impact.

“We identified between $20,000 to $30,000 worth of hoses on a single machine,” Jason said.

"The call out fees and costs associated with getting a hose replaced were unsustainable. We needed support that our current suppliers weren’t providing. I know Cat products are a cut above the rest – there’s no comparison.”

So, Jason turned to leading Cat dealer WesTrac seeking a solution.

DJ and JA Brooker chose WesTrac as a partner because it wished to work with a Caterpillar dealer that was able to guarantee continuous support and could offer a technically advanced solution based on their fleet operations.

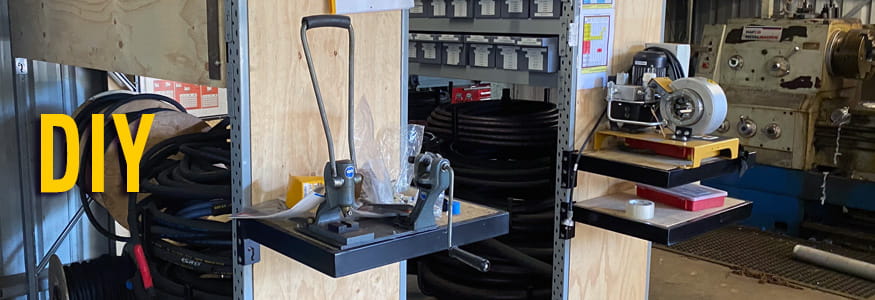

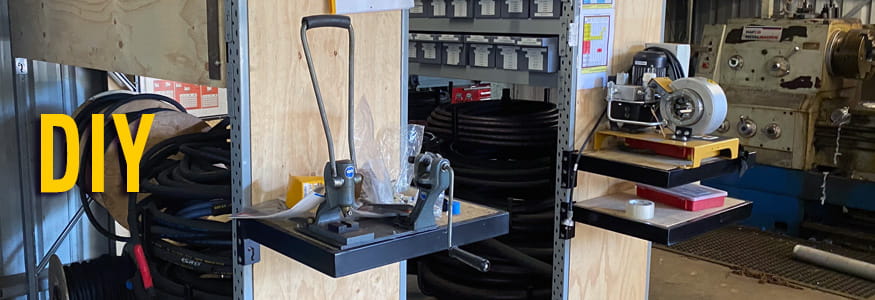

The combination of a Cat Hose Crimper, access to Cat’s Hydraulic Information System (HIS) for identifying and ordering parts, and the market-leading quality of Cat hoses has allowed the Northern Rivers, NSW earthmoving contractor to keep its fleet running for longer and to manage repairs and maintenance in a fraction of the time it once took.

HIS acts like a search engine for hydraulic hoses supporting DJ and JA Brooker on planning the resources they need to order and build hoses on demand, adhering to strict Caterpillar specifications and standards, without any delivery delays or added costs. WesTrac hose solutions can be tailored to suit customer needs and individual requirements, and are designed to ensure profitability and efficiency.

Jason says access to HIS was a major reason for deciding to go with the solution.

“It’s like ordering the parts you need off eBay – search the part number in the system, hit the button and it’s delivered,” he said.

"Then when we have periods of bad weather, we allocate time to hose assembly.”

When asked how the solution has impacted their bottom-line, Jason says the reduction in downtime and cost savings have been significant.

“We’re now staying ahead,” he said.

“We monitor the number of hours a machine performs and prepare new fixtures before they need to be replaced. The reduction we’ve seen in downtime is invaluable.”

Jason continues. “People’s jaws drop when they realise we’re now running our machines at 20,000-odd hours, up from an average of 10,000 hours before we reached out to WesTrac. Back then, it wasn’t uncommon for a machine to blow nine hoses in three months. These days we’re lucky to blow three hoses in six months.”

Jason says it is the support that WesTrac and Caterpillar provide that fosters their long-term relationship.

“The WesTrac team are fantastic and have gone above and beyond to look after us,” Jason said.

"It’s not just the quality Caterpillar and WesTrac deliver - it’s their resources, stock and inventory which are all an asset to our business. You don’t expect to develop rapport with big entities like WesTrac or Caterpillar. But the relationship I have with their teams reflects the one I have with the local bloke at the corner store.”