Minimising risk on mine sites by reducing false alarms

It seems a bit counter-intuitive that by reducing the alarms and alerts to machinery operators, you can reduce risks. But that’s exactly what WesTrac’s new Terrain Dynamic Avoidance Zones technology – or TDAZ as we affectionately call it – is designed to do.

Let’s start by looking back a few years to see what the specific problem involves.

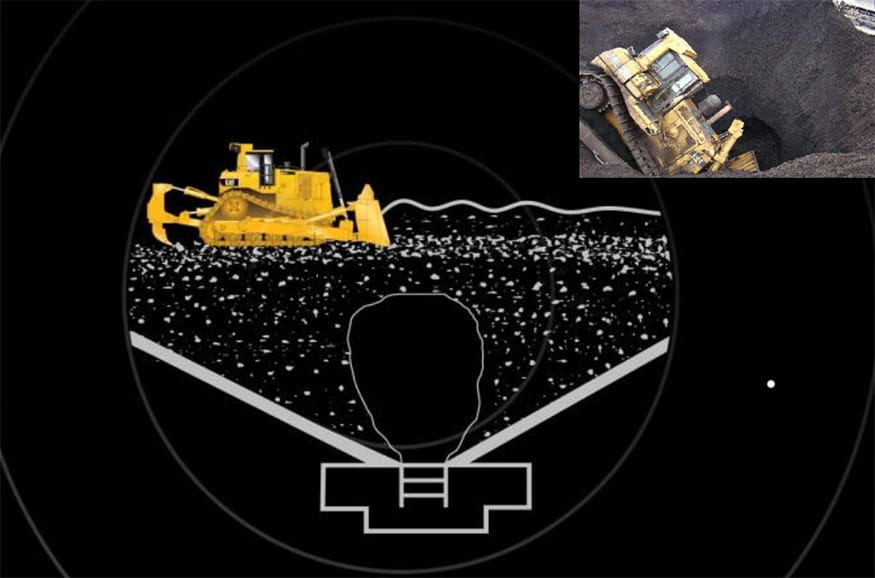

It is to do with “bridging”. That’s when material gets stuck and forms an arch or bridge above feeder funnels or gantries. The bridge that forms can support a reasonable amount of weight so material builds up and covers the opening, leaving a void beneath it.

A few decades ago, there was a problem with dozers falling into those voids and there were unfortunately numerous fatalities, typically related to material ingress into the cab.

The initial response was to cover off some of the risks by fitting things like 30psi glass and self-rescuer units to give operators a chance of survival until they could be retrieved.

But the bigger issue, and better outcome, was coming up with a way to avoid the problem altogether of engulfment of dozers into valves at Coal Handling Preparation Plants (CHPP). It can also be a risk for iron ore load out facilities.

Dozers come with a standard level of smarts – things like in-cylinder sensors, blade control and various automation features – then we add a layer of technology over the top called Terrain, which is one of the pillars of the Cat MineStar solution, that provides high-precision GPS or guidance.

Terrain essentially provides information on where the machine is working, what height it’s working at, what material it’s moving and where. You can start to track material movements, work to a design and enter 3D objects into the avoidance zones.

Using it, we can set up geofencing around things like concrete bollards, overhead gantries and valves, and when an operator gets too close to that obstacle an alarm will sound in the cab to warn them.

But one of the unfortunate things about alarms is that if they go off too often and the operators become numb to them. The right solution is not to bombard them with too many alarms that are not a genuine risk.

That’s what TDAZ is all about. The technology talks between the Supervisory Control and Data Acquisition (SCADA) system in the CHPP and the onboard Terrain system, identifying when valves are open and closed.

When valves are closed, the risk of engulfment is reduced, and the alarms minimised or turned off.

If a valve opens again and the risk of bridging increases, the alarms become active again and if an operator comes into close proximity, they’ll receive an alert.

One of the things we’re very conscious of at WesTrac is to not just sell fancy widgets – we want to partner with our customers to help solve real world problems and save lives.

This kind of solution offers the opportunity to partner with our customers. Integration of various third-party and in-house systems is necessary, means a high degree of trust and collaboration is required.

So where’s the value in the TDAZ system for you?

The value lies in gaining the most benefits from Terrain.

What we are ultimately doing is providing a layer between the operating system for the prep plant and the high-precision GPS onboard the dozer. This prevents operators from becoming numb to alarms. By reducing that risk, we are delivering enhanced safety performance.

TDAZ is available now – it’s been in development with a NSW coal mining customer for about 18 months and can now be rolled out and tailored for any site where it can offer benefits.

If you’re reading this and you have any further questions about how TDAZ works or what is required to implement it at your site, reach out to me directly via DM on LinkedIn, message me via the WesTrac website or ask your question in the comments on our socials.

Having the right equipment is just one step to ensure success. Once that equipment is operational, the key to success is staying on top of machine health and maintenance requirements. Group Manager Client Solutions CHELSEA GRAY explains.