Preventative maintenance through oil analysis

Fluid analysis (including oil analysis) is a critical component of equipment maintenance and is used to identify potential issues before they become major problems.

Equipment maintenance is crucial in ensuring optimal performance, safety and longevity of any fleet, not just a Cat® fleet.

Fluid analysis (including oil analysis) is a critical component of equipment maintenance and is used to identify potential issues before they become major problems.

Effective preventative maintenance is estimated to be three to ten times more cost-effective than unscheduled maintenance and repair, and scheduled oil sampling (SOS) should form a key part of any preventative maintenance program.

With the use of SOS oil sample kits and other oil analysis tools, WesTrac technicians not only evaluate if fluids need to be changed, but also identify any underlying issues that need to be addressed to keep your Cat® machinery running.

Just as you can tell a lot about a person by analysing a blood sample, you can understand what’s happening inside your machine with fluid sampling. As WesTrac Product Support and Sales Representative SARNDRA FEAST explains, it is all about identifying potential issues before they become serious and helping to optimise performance.

Oil analysis is typically done using an oil test kit or oil sampling kit and is a vital process in maintaining your fleet for optimal performance.

Fluid analysis tests help detect abnormal wear and identify contaminants such as dirt and water in lubrication systems. Monitoring oil condition and detecting potential problems early can prevent breakdowns and save on repair costs.

Oil sampling programs such as WesTrac’s Cat® SOS™ Services Program, makes it possible to put your machines on the optimal service interval and identify problems across critical systems before they impact your operations.

Keep reading below to find out more or reach out to our SOS team by filling out the form.

You can evaluate the performance and condition of your machinery through the use of our oil sample kits to allow final drive oil, hydraulic oil and engine oil testing.

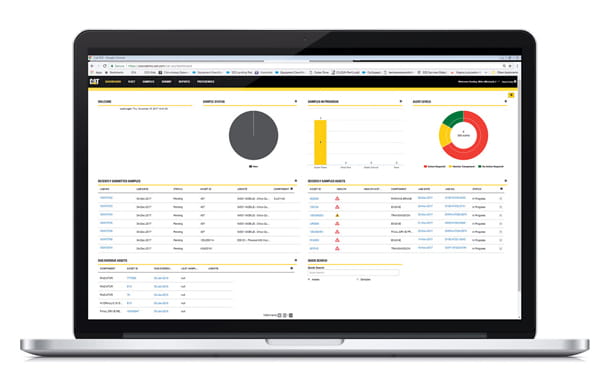

WesTrac’s Cat® SOS™ Services Program is an ongoing commitment to protect your equipment’s value and performance. It combines the simple process of fluid sampling with state-of-the-art analysis and clear reporting via the Cat S•O•S Web online tool.

The program will provide you with a number of benefits.

WesTrac’s SOS oil sample kits allow for comprehensive fluid analysis testing, evaluating over 30 characteristics from each sample.

Our engine oil sample analysis includes:

Discover the benefits of fluid analysis testing and how to test engine oil with our oil sample kits and analysis services.

The Cat® SOS™ Services Program is a mutual commitment to protect the performance and value built into your Cat® equipment.

The industry-leading program combines the simple process of fluid sampling with state-of-the-art analysis and clear reporting via Cat® SOS Web.

By fluid sampling with WesTrac, you’ll see what’s going on inside your machinery and detect problems before they become serious, enabling optimised performance.